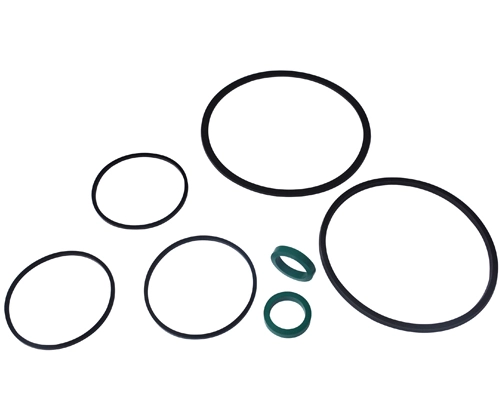

Types of Ship Sealing Rings for Sale

What Is the Purpose of Marine Rubber Seals?

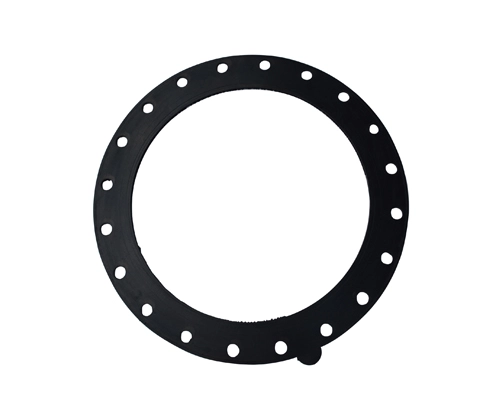

1. Marine rubber seals, such as rubber rings for ship sealing, prevent liquid escape or gas leakage under pressure, ensuring system integrity and functionality.

2. The marine rubber seals prevent contaminants from entering the system, keeping the fluid clean and free of any external particles.

3. Ship sealing elements and other marine rubber seals help keep moving parts functioning properly, providing the necessary lubrication to minimize friction and wear.

4. In industries involving hazardous or toxic substances, the marine rubber seals play a vital role in preventing leaks that may pose a threat to human health or the environment, providing a reliable barrier and reducing the risk of accidents or contamination.

How Do Rings for Ship Sealing Work?

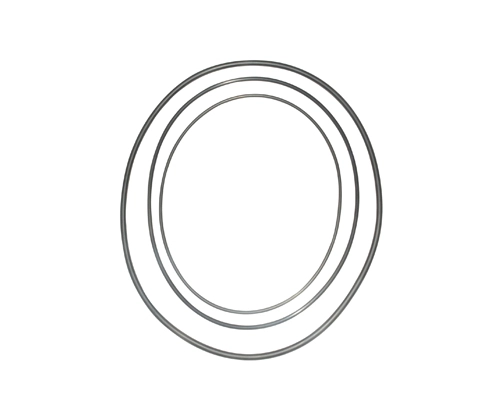

1. Rings for ship sealing, are usually made of elastomeric materials such as rubber, silicone and fluoroelastomer. These materials have good elasticity and can be restored to their original shape.

2. These marine rubber seals are installed between two parts that are moving relative to each other and are usually located in a sealing groove. When the two parts engage with each other, the seal will be squeezed and deformed. This deformation is due to the elasticity of the seal.

3. When two parts move against each other, the ship sealing element is squeezed and fills the sealing groove. This causes the seal to exert uniform pressure on the two surfaces moving against each other. The deformation of the seal causes it to fit and close the gap between the two parts, thus preventing the leakage of liquids or gases.

4. The rings for ship sealing have good resistance to high pressures and temperatures, but their performance can be affected by the choice of material. Different types of sealing materials are suitable for different working conditions.

5. These marine rubber seals can be used for both static and dynamic sealing. In a static sealing application, the two components are stationary relative to each other, while in a dynamic sealing application, the two components move relative to each other. Seals can be adapted to both situations and provide a reliable seal.

-

Mar 14 , 2025Case Study: Small Dredging Project at a Local MarinaA small marina had faced gradual sediment buildup over the years, reducing its water depth and creating navigation hazards for boats. The objective of this small dredging project was to remove the acc...

Mar 14 , 2025Case Study: Small Dredging Project at a Local MarinaA small marina had faced gradual sediment buildup over the years, reducing its water depth and creating navigation hazards for boats. The objective of this small dredging project was to remove the acc... -

Mar 13 , 2025Durable and Reliable Rubber Dredging Hose SolutionsDurable and reliable rubber dredging hose solutions stand as indispensable components within a myriad of marine and industrial settings, particularly entrenched in the realm of dredging endeavors. Tai...

Mar 13 , 2025Durable and Reliable Rubber Dredging Hose SolutionsDurable and reliable rubber dredging hose solutions stand as indispensable components within a myriad of marine and industrial settings, particularly entrenched in the realm of dredging endeavors. Tai... -

Mar 12 , 2025Flexibility and Customization: The Core Competitiveness of Dredge Rubber HosesIn the modern dredging industry, dredge hose manufacturers such as Danyang Yonghong Marine Rubber are enhancing flexibility and customization to provide efficient, durable, and adaptable solutions for...

Mar 12 , 2025Flexibility and Customization: The Core Competitiveness of Dredge Rubber HosesIn the modern dredging industry, dredge hose manufacturers such as Danyang Yonghong Marine Rubber are enhancing flexibility and customization to provide efficient, durable, and adaptable solutions for...

- Maintenance Tips for Prolonging the Life of Your Dredging Hoses

- The Unique Advantages of Floating Dredging Hoses

- The Difference Between Dredge Discharge Hose and Dredging Hose

- Structural Design and Application Advantages of Armored Hose

- The Role of Sewer Seal Rings in Marine Pollution Prevention

- Rubber Fender For Ship: A New Type of Fender Equipment

- Situation and Development of the Dredge Rubber Hose

English

English