In various ship engineering projects, especially in liquid or gas delivery systems, armored hoses act as critical connectors, fulfilling important functions. They are primarily used in environments requiring high pressure resistance, corrosion resistance, and resistance to external impact, ensuring the safe operation of ships in harsh sea conditions. The design structure of shipboard armored hoses is very unique, capable of meeting the operational requirements of ships under various complex conditions. Below are the main components of an armored hose and how they function in practical applications.

Inner Core Tube: Ensuring Safe Medium Transmission

The inner core tube of an armored hose is its core component, responsible for carrying and transmitting the liquid or gas medium in the ship's system. The inner core tube is usually made of high-strength, corrosion-resistant materials, featuring high pressure and high temperature resistance properties. The choice of the inner core tube is directly related to the hose's transmission stability, ensuring that the transmission of liquid or gas in harsh marine environments is not affected by external conditions.

Pressure Armour Layer: Enhancing Pressure Resistance

To maintain stable operation in high-pressure environments, the armored hose is also designed with a pressure armour layer. This layer typically utilizes steel wire weaving or steel strip wrapping to enhance the hose's pressure resistance. The pressure armour layer of the armored hose can effectively withstand the high pressures that may occur in the ship's system and can prevent external impacts from damaging the hose.

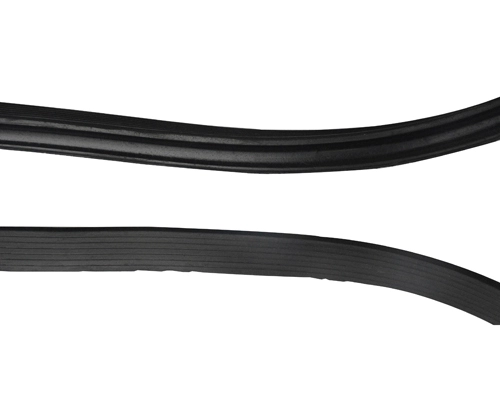

Tensile Armour Layer: Improving Tensile Strength

The tensile armour layer of an armored hose is another crucial protective layer. It enhances the hose's tensile strength through steel wire winding or metal wire weaving, effectively preventing hose damage caused by external tension or bending during ship movement. This layer ensures that the hose can withstand significant tensile forces during maritime navigation, especially when the ship changes direction or encounters adverse weather, maintaining the integrity and stability of the armored hose.

Outer Protective Layer: Providing Additional Protection

The outer protective layer of the armored hose primarily serves protective and wear-resistant functions. The outer protective layer is typically made of high-strength rubber or polyurethane material, offering good corrosion resistance, wear resistance, and UV resistance. It can effectively protect the hose from environmental factors such as seawater, salt spray, and chemicals, while also preventing external objects from scratching or wearing the hose during loading, unloading, or operation, thus extending the service life of the armored hose.

High Adaptability: Meeting Harsh Working Environments of Ships

The multi-layer structure design of the armored hose allows it to maintain excellent operational performance in harsh marine environments. Whether under high pressure, low temperatures, or in situations involving strong impact or bending, the inner core tube, pressure armour layer, tensile armour layer, and outer protective layer of the armored hose work together to ensure the stability and safety of the hose system. This design not only enhances the physical performance of the armored hose but also improves its adaptability in complex environments, ensuring the normal operation of ship systems.

Shipboard armored hoses, with their precision-matched multi-layer structure design, can meet the operational requirements of ships in harsh sea conditions. Choosing high-quality armored hoses can ensure the safety and stability of ships in complex marine environments. Yonghong offers high-quality shipboard armored hoses in various specifications and materials, leveraging excellent structural design and performance to assist your ship systems in operating efficiently and safely.

- Situation and Development of the Dredge Rubber Hose

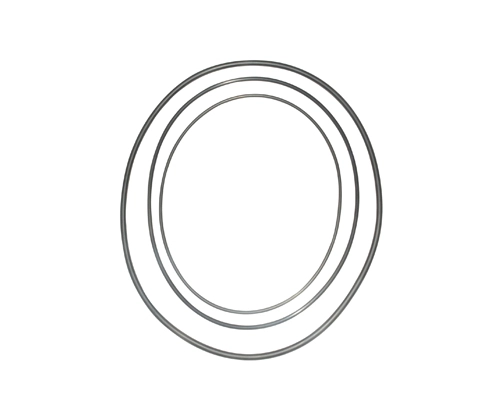

- Sewer Seal Ring: Securing Urban Infrastructure

- Armored Self-Floating Rubber Pipe: A Comprehensive Overview

- Applications of Polymer Materials and Composite Materials in Marine Rubber Seals

- Maintenance Tips for Prolonging the Life of Your Dredging Hoses

- Durable and Reliable Rubber Dredging Hose Solutions

English

English