A small marina had faced gradual sediment buildup over the years, reducing its water depth and creating navigation hazards for boats. The objective of this small dredging project was to remove the accumulated silt and sand, restoring the marina to a safe depth for vessel access.

Solution

1. Site Assessment

The team evaluated the marina to estimate the volume of sediment (primarily silt and sand) and identified a nearby disposal site for the dredged material.

2. Equipment Selection

A small cutter suction dredger was chosen for its ability to cut through sediment and pump it away efficiently.

A critical component was the dredge discharge hose, especially offered by dredge rubber hose manufacturers, which had to meet specific requirements:

Flexibility: To navigate around docks and boats.

Durability: To resist abrasion from the sandy slurry.

Size: Appropriate diameter to maintain flow without clogging.

Additionally, the team selected a self floating rubber hose to ensure buoyancy in the water and an armor flex hose to provide additional strength and protection against potential punctures.

3. Dredging Operation

The dredger was deployed in the marina, cutting and suctioning the sediment.

The discharge hose was connected to transport the material to the disposal site, carefully routed to avoid marina infrastructure. Its reinforced design, including a sealing element in china, ensured it could handle the abrasive sediment without tearing or wearing out. A sewer seal ring was also used to maintain a watertight connection and prevent leaks.

4. . Project Completion

Once the target depth was achieved, the equipment was removed, and the marina was restored with minimal impact on its operations.

The dredging project successfully restored the marina’s depth, ensuring safe navigation for boats. The operation underscored the importance of using reliable, well-suited equipment—especially the dredge discharge hose, which played a pivotal role in transporting the dredged material efficiently and without incident.

The Role of Quality Discharge Hoses in Dredging

In small dredging projects like this one, the dredge discharge hose is essential for success. It must be:

Durable: Capable of withstanding abrasion and harsh conditions.

Flexible: Easy to maneuver in confined or complex environments.

Efficient: Designed to maintain steady flow rates and reduce operational delays.

For a project like the marina dredging, a lightweight yet robust hose was key to quick setup and effective performance.

Danyang Yonghong Marine Rubber

For your dredging needs, trust Danyang Yonghong Marine Rubber, a professional manufacturer specializing in high-quality dredge discharge hoses. Their products are engineered to meet the demands of projects big and small, ensuring reliability and performance every time.

Why Choose Danyang Yonghong Marine Rubber?

Exceptional Durability: Their hoses are built to resist abrasion, corrosion, and tough environmental conditions.

Superior Flexibility: Easy to handle and position, perfect for projects with spatial challenges.

Custom Solutions: Available in various sizes and specifications tailored to your specific project.

Industry Expertise: Backed by years of experience, their team offers expert guidance to help you select the right hose.

Contact Them Today

Ensure your next dredging project runs smoothly with top-tier dredge discharge hose from Danyang Yonghong Marine Rubber. Reach out to their knowledgeable team to discuss your needs and discover how their products can support your success.

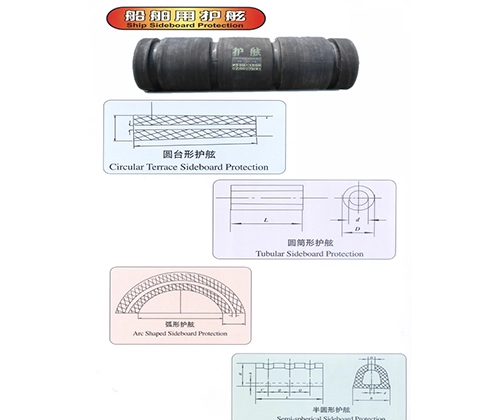

- Rubber Fender For Ship: A New Type of Fender Equipment

- The Difference Between Dredge Discharge Hose and Dredging Hose

- Armored Self-Floating Rubber Pipe: A Comprehensive Overview

- Why Rubber Fenders Are Essential Devices For Ships?

- Structural Design and Application Advantages of Armored Hose

- Maximize Your Dredging Efficiency with Premium Rubber Suction Hoses

English

English