Types of Large Diameter Rubber Hose

-

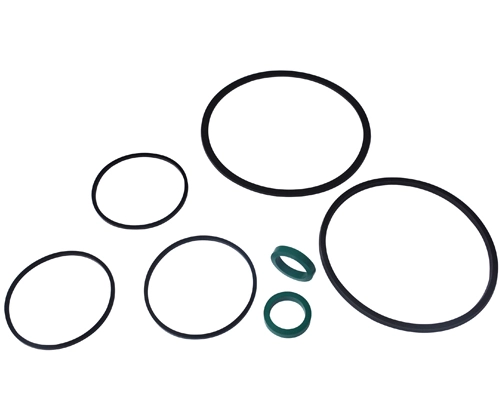

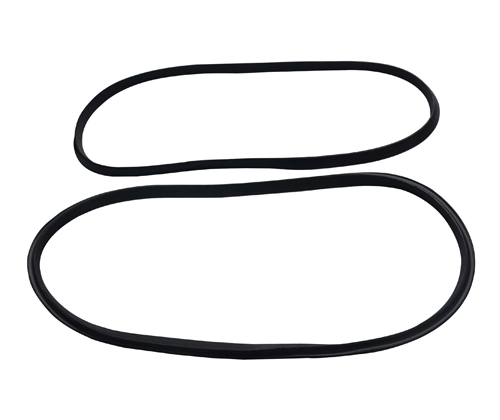

Rectangular Sealing Ring

Outstanding Features of Rectangular Sealing RingThe compression rate of rectangular rings is usually 40% to 50%;The higher compression rate of rectangular rings makes them more suitable for situations... -

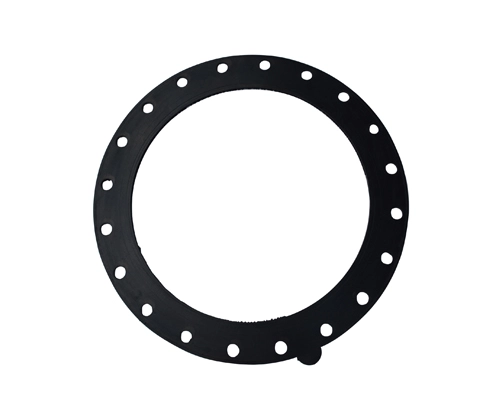

Rubber Gasket

Outstanding Features of Rubber GasketRubber gaskets have good sealing performance and can effectively prevent the leakage of liquids or gases;It has good temperature resistance, and different rubber m... -

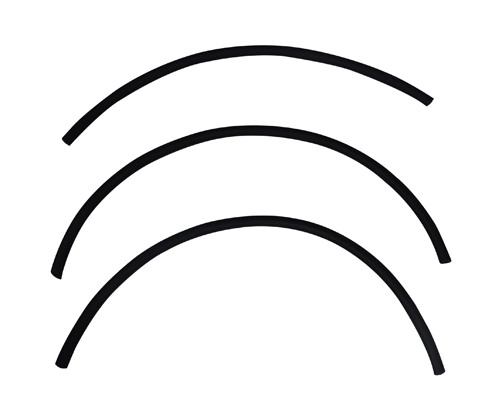

Sealing Rubber Strip

Outstanding Features of Sealing Rubber StripMost of them are made of Ding Qing material sealing stripsGood performance balanceHas excellent weather resistanceOzone resistance performanceHeat aging res... -

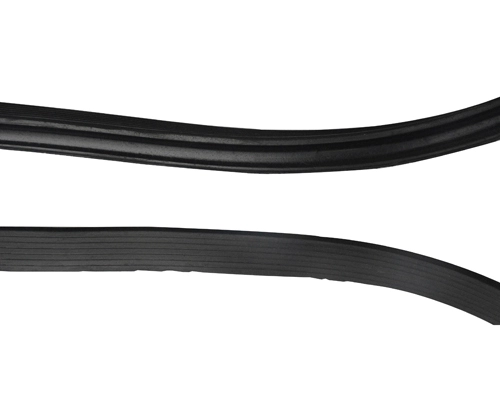

Marine Rubber Parts

Outstanding Features of Rubber Miscellaneous PartsAccording to the specific requirements of product materials and processes, different rubber raw materials are selected to produce different rubber mis... -

Wedge Rubber Ring

Outstanding Features of Wedge Rubber RingEnsure the sealing of the pipeline, prevent water leakage The occurrence of air leakage and other phenomena avoids the loss of groundwater resources and soil e... -

Pipe Jacking Rubber Ring

Outstanding Features of Pipe Jacking Rubber RingEnsuring the sealing of pipelines, preventing water and gas leakage, thereby avoiding the loss of groundwater resources and soil erosion. -

Rubber Ring for Enterprise Mouth

Outstanding Features of Rubber Ring for Enterprise MouthEnsuring the sealing of pipelines, preventing water and gas leakage, thereby avoiding the loss of groundwater resources and soil erosion.

Hot-Sale Large Diameter Rubber Hose

-

Advantages of YongHong Industrial Rubber Hose

The company is a collection of research and development, manufacturing, sales, after-sales in one of the professional dredge rubber hose manufacturers of China Dredging Association of ship rubber designated production base, the company is equipped with sophisticated production equipment, advanced processing technology, complete testing means, perfect quality assurance system, through the Iso9001: 2000 international quality system certification. Registered trademark ''Yonghong''. The company has a complete range of products, always following the ''quality first, customer first'' principle, vigorously developing new products, and constantly innovating.

-

Industrial Rubber Products: Manufacturing Processes and Quality Control

The manufacturing process of industrial rubber products involves meticulous steps, starting from raw material selection to final product testing. Initially, high-quality rubber is mixed with specific compounds to enhance its properties. This mixture is then molded, extruded, or vulcanized into the desired shape, depending on the product’s application. Throughout production, rigorous quality control measures are implemented, including dimensional checks, physical property testing, and durability assessments. These steps ensure that each product meets strict standards for performance and reliability. By adhering to these protocols, manufacturers guarantee that their rubber products can withstand the demands of industrial use, providing durability, flexibility, and resistance to harsh environments.

-

Innovations in Rubber Compounding for Industrial Use

Innovations in industrial rubber compounding have revolutionized product performance and sustainability. Advanced techniques now allow for the integration of recycled materials without compromising quality, significantly reducing environmental impact. Additionally, the development of new formulations has enhanced rubber’s resistance to extreme temperatures, chemicals, and wear. These breakthroughs not only extend the lifespan of rubber products but also broaden their application in challenging industrial environments, marking a significant leap forward in material science and engineering.

Industrial Rubber Hose FAQs

-

Q What are the key features of your dredging hoses?

Dredging hose is constructed from premium, wear-resistant materials.

Dredging hose offers outstanding flexibility, ensuring smooth operation across diverse environments.

Dredging hose exhibits superior resistance to abrasion, tearing, and environmental conditions.

-

Q What are the maintenance requirements for the rubber hose?

The maintenance requirements for the hose include regular inspections to check for signs of wear, damage, or leaks. It is recommended to inspect the hose before and after each use to ensure it is in good condition. Additionally, periodic maintenance should involve cleaning the hose to remove any debris or buildup that could affect its performance.

-

Q What are the functions of sealing rubber strip?

Rubber sealing strips play a crucial role in the sealing of ships. During navigation, ships need to withstand various harsh marine environments, such as seawater corrosion and wave impact. Rubber sealing strips can effectively prevent the infiltration of seawater and other liquids, ensuring the internal sealing of the ship and avoiding accidents caused by water ingress.

-

Q What are your hot-sale products?

Including armored self-floating rubber pipe, self-floating rubber hose and discharge hose.

-

Mar 14 , 2025Case Study: Small Dredging Project at a Local MarinaA small marina had faced gradual sediment buildup over the years, reducing its water depth and creating navigation hazards for boats. The objective of this small dredging project was to remove the acc...

Mar 14 , 2025Case Study: Small Dredging Project at a Local MarinaA small marina had faced gradual sediment buildup over the years, reducing its water depth and creating navigation hazards for boats. The objective of this small dredging project was to remove the acc... -

Mar 13 , 2025Durable and Reliable Rubber Dredging Hose SolutionsDurable and reliable rubber dredging hose solutions stand as indispensable components within a myriad of marine and industrial settings, particularly entrenched in the realm of dredging endeavors. Tai...

Mar 13 , 2025Durable and Reliable Rubber Dredging Hose SolutionsDurable and reliable rubber dredging hose solutions stand as indispensable components within a myriad of marine and industrial settings, particularly entrenched in the realm of dredging endeavors. Tai... -

Mar 12 , 2025Flexibility and Customization: The Core Competitiveness of Dredge Rubber HosesIn the modern dredging industry, dredge hose manufacturers such as Danyang Yonghong Marine Rubber are enhancing flexibility and customization to provide efficient, durable, and adaptable solutions for...

Mar 12 , 2025Flexibility and Customization: The Core Competitiveness of Dredge Rubber HosesIn the modern dredging industry, dredge hose manufacturers such as Danyang Yonghong Marine Rubber are enhancing flexibility and customization to provide efficient, durable, and adaptable solutions for...

- Maintenance Tips for Prolonging the Life of Your Dredging Hoses

- The Unique Advantages of Floating Dredging Hoses

- The Difference Between Dredge Discharge Hose and Dredging Hose

- Structural Design and Application Advantages of Armored Hose

- The Role of Sewer Seal Rings in Marine Pollution Prevention

- Rubber Fender For Ship: A New Type of Fender Equipment

- Situation and Development of the Dredge Rubber Hose

English

English