Choosing the right flexible dredge hose is crucial for ensuring the efficiency and safety of dredging projects. Flexible dredge hoses are key components used in dredging operations to transport mixtures such as sediment and water, and their performance directly affects the efficiency and cost of dredging operations.

Material

The material of the flexible dredge hose needs to be selected based on the corrosiveness and abrasiveness of the transported medium as well as the working environment. Common materials include steel, cast iron, and high-density polyethylene (HDPE). For example, HDPE pipes have good wear resistance and corrosion resistance, making them suitable for transporting sediment.

Diameter and Wall Thickness

The diameter and wall thickness of the flexible dredge hose directly affect its transport capacity. The larger the diameter, the stronger the transport capacity, but this also increases the weight and cost of the pipe. Wall thickness determines the pipe's pressure resistance and wear resistance. The appropriate diameter and wall thickness should be selected based on the specific needs and budget of the dredging project.

Connection Method

The connection method of the flexible dredge hose, such as the armor flex hose, needs to be simple and reliable to facilitate quick installation and maintenance. Common connection methods include flange connections, welding, and clamp connections. Flange connections are suitable for situations requiring frequent disassembly, while welding is suitable for fixed installations.

Aging Resistance and Temperature Resistance

Flexible dredge hoses need to have good aging resistance to adapt to prolonged outdoor exposure. Additionally, temperature resistance is another factor to consider, especially when working in high or low-temperature environments.

Reputation and Service of the Flexible Dredge Hose Suppliers

When selecting dredge rubber hose suppliers, the reputation and service of the dredge hose suppliers are also important factors. Reliable suppliers can not only provide high-quality products but also offer timely after-sales service and technical support.

Choose YongHong among Flexible Dredge Hose Suppliers

Industry Authority Certification

As the designated rubber production base by the China Dredging Association, YongHong not only represents industry recognition and trust but also showcases its professional status and deep expertise in the dredging field.

International Quality Management System Certification

Having passed the ISO9001:2000 international quality system certification means that YongHong has met international standards in production management, quality control, and customer service. This ensures that every stage, from raw material procurement to finished products leaving the factory, strictly follows high-quality standards, providing customers with stable and reliable products.

Reputation as a Well-Known Brand

As a well-known trademark in Zhenjiang City, this not only represents the brand's popularity and influence but is also a reflection of the market's continuous recognition of YongHong's product quality and service. This brand honor helps build customer confidence and long-term stable cooperative relationships.

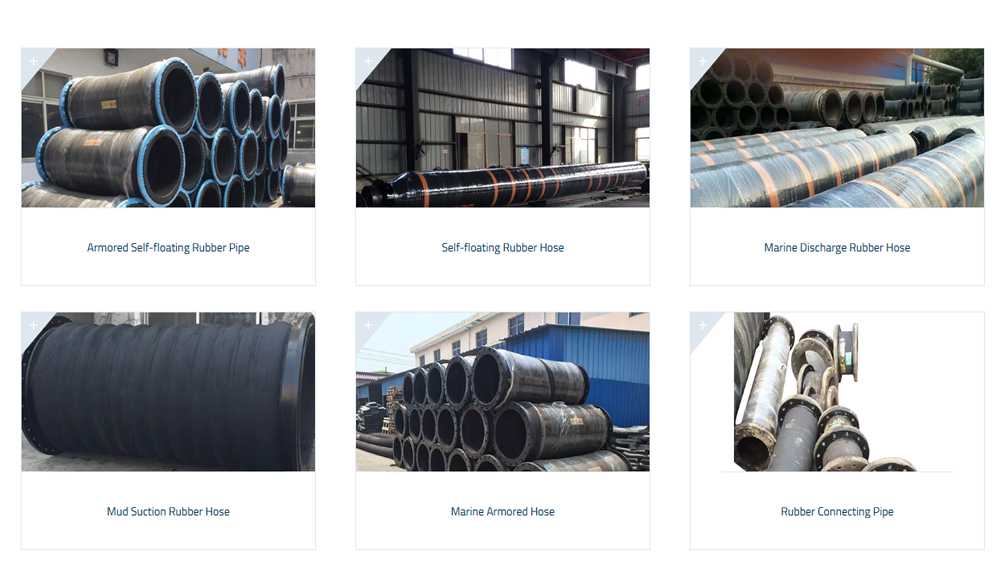

Diverse Product Range

YongHong offers an extremely rich product line, covering dredging rubber hoses (including EVA mud pipes), dredging rubber pipes, fenders, mud door linings, mud door rubber strips, suction pump inlet rings, gate seals, O-rings, V-rings, oil seals, and sewer seal ring series. These products can meet the diverse needs of different dredging projects, providing customers with one-stop solutions.

Popular Search Terms from YongHong

- Maintenance Tips for Prolonging the Life of Your Dredging Hoses

- Self-Floating Dredge Hose: A Competent Assistant in Hydraulic Engineering

- Why Do Rubber Fenders Come in Different Colors?

- Flexibility and Customization: The Core Competitiveness of Dredge Rubber Hoses

- Maximize Your Dredging Efficiency with Premium Rubber Suction Hoses

- Structural Design and Application Advantages of Armored Hose

English

English