Types and Functions of Dredging Rubber Hoses

Dredging rubber hoses are specially designed hoses for underwater or slurry environments. Their main function is to effectively transport or extract solid and liquid materials in water or slurry. Based on different application scenarios, dredging rubber hoses are mainly divided into two categories: flange dredging rubber hoses and suction dredging rubber hoses. Flange dredging rubber hoses are connected via flanges and are suitable for dredging operations that require high pressure and high flow; suction dredging rubber hoses, on the other hand, focus more on suction functions and are commonly used in slurry extraction, riverbed cleaning, and similar operations. YONGHONG dredge rubber hose factory produces a wide range of these hoses to meet various needs.

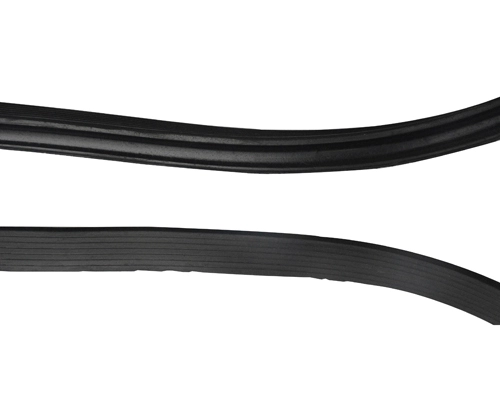

Performance Advantages of Dredging Rubber Hoses

Owing to their unique performance advantages, dredging rubber hoses play an important role in many underwater engineering projects. They not only exhibit good tensile strength, capable of withstanding considerable pressure to protect the pipeline from external damage, but also have fully sealed negative pressure resistance, ensuring stable operation in high-pressure or negative pressure environments. Moreover, dredging rubber hoses demonstrate excellent properties such as impact resistance, wear resistance, corrosion resistance, and aging resistance, enabling long-term use in harsh marine and river environments without failure. Their design of seamless forming further enhances the strength and sealing of the hose, ensuring safe and efficient transport processes. Our self floating dredge hose and armored hose are prime examples of these high-performance products.

Application Fields and Installation Convenience of Dredging Rubber Hoses

Dredging rubber hoses are widely used in marine engineering, lake and river dredging, tunnel construction, port construction, and various other fields. In marine engineering, they serve as underwater transport pipelines, providing crucial support for deep-sea resource development; in lake and river dredging, they become essential tools for riverbed and channel cleaning; in tunnel and port construction, they undertake important tasks such as drainage and sludge removal. Notably, dredging rubber hoses not only have excellent performance but are also extremely convenient to install, offering flexible and safe use, greatly saving project time and costs. As one of the leading dredge rubber hose suppliers, we ensure that our products are easy to install and highly reliable.

Future Development of Dredging Rubber Hoses

With the continuous advancement of science and technology, the performance of dredging rubber hoses is also continuously improving and innovating. The application of new materials and the introduction of new processes have significantly enhanced the strength, wear resistance, and corrosion resistance of dredging rubber hoses. At the same time, the integration of smart and automated technologies also shows new potential in aspects such as remote control and real-time monitoring. In the future, dredging rubber hoses will play an increasingly important role in the field of underwater engineering, contributing more to human endeavors in ocean resource development, channel construction, and environmental protection.

Other Marine Rubber Series You May Also Like

- The Difference Between Dredge Discharge Hose and Dredging Hose

- Comparison of Floating Rubber Hose with Other Types of Hoses

- Situation and Development of the Dredge Rubber Hose

- Installation Process of Marine Rubber Fender

- Sewer Seal Ring: Securing Urban Infrastructure

- Why Rubber Fenders Are Essential Devices For Ships?

English

English