Types of Sewer Rings for Ships

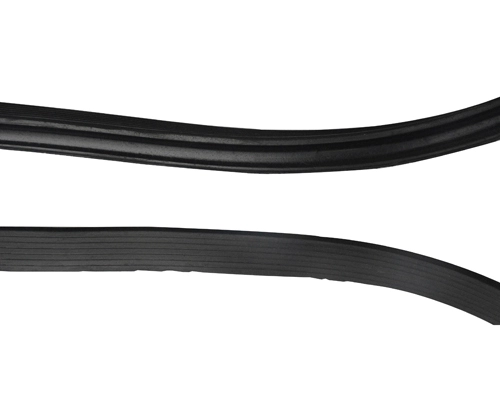

The Role of Rubber Rings in Sewer Pipe Connections

Rubber sewer rings are essential in connecting drainage pipes, as they create a watertight seal that prevents leaks and ensures the system’s integrity. The elasticity of sewer seal rings allows for slight movements and adjustments, accommodating pipe expansions and contractions. This flexibility helps maintain a secure and durable connection, even under varying pressure conditions. Additionally, these sewer rings are resistant to corrosion and chemical damage, making them ideal for long-term use in plumbing systems.

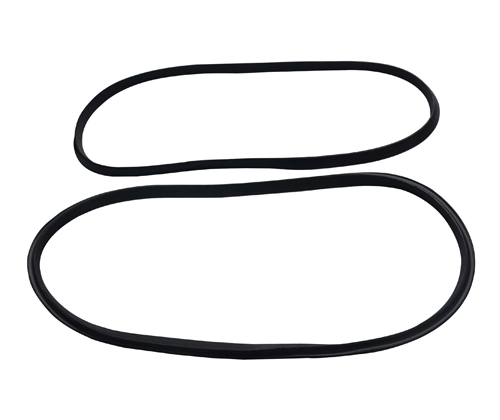

Material Selection for Sewer Rings

Size: When purchasing sewer pipe gaskets and other sewer seal rings, you should choose the suitable sewer gasket according to the size of the downpipe.

Material: Choose the suitable material according to the usage environment. For example, PVC sewer seal rings with shorter service life are suitable for cold water pipes, while high temperature resistant rubber and silicone sewer pipe gaskets are suitable for hot water pipes or high temperature environments.

Durability: In order to ensure the effect of long-term use, it is recommended to purchase a sewer seal ring with a longer service life, depending on the material.

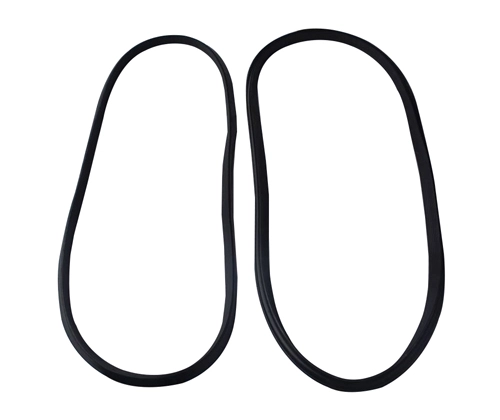

Maintenance and Care Recommendations for Rubber Sewer Rings

In addition to choosing the right sewer seal ring, you also need to pay attention to its maintenance and upkeep. Here are some suggestions and tips:

Regular Inspection: Regularly inspect the sewer ring for any signs of wear, cracks, or damage. Early detection can prevent leaks and other issues.

Cleaning: Ensure that the area around the sewer seal ring is kept clean. Remove any debris or buildup that could compromise the seal. You can use mild cleaning agents to avoid damaging the material of the seal ring.

Avoid Harsh Chemicals: Be cautious with the use of harsh chemicals or cleaners that could degrade the material of the sewer ring. Opt for products that are safe for use with rubber or the specific material of your sewer seal ring.

Proper Installation: Ensure that the sewer seal ring is properly installed. An improperly installed sewer seal ring can lead to leaks and other issues. If you’re unsure, consult a professional for installation.

Watch for Debris: Avoid allowing foreign objects or solid substances to enter the drain, as they can cause damage to the seal ring. Items such as grease, sanitary napkins, and other debris should be disposed of properly.

Recommended Replacement: Sewer seal rings wear out over time due to exposure to various elements and usage. It is recommended to replace them once a year or as needed to ensure a proper seal and prevent leaks.

-

Apr 23 , 2025Comparison of Floating Rubber Hose with Other Types of HosesFloating rubber hoses are widely used in offshore engineering, dredging operations, and oil transportation. Compared to other types of hoses, floating rubber hoses perform outstandingly in several asp...

Apr 23 , 2025Comparison of Floating Rubber Hose with Other Types of HosesFloating rubber hoses are widely used in offshore engineering, dredging operations, and oil transportation. Compared to other types of hoses, floating rubber hoses perform outstandingly in several asp... -

Apr 15 , 2025Self-Floating Dredge Hose: A Competent Assistant in Hydraulic EngineeringIn hydraulic engineering, dredging operations are essential for ensuring smooth waterways and preventing floods. With continuous technological advancements, traditional dredging methods are gradually ...

Apr 15 , 2025Self-Floating Dredge Hose: A Competent Assistant in Hydraulic EngineeringIn hydraulic engineering, dredging operations are essential for ensuring smooth waterways and preventing floods. With continuous technological advancements, traditional dredging methods are gradually ... -

Apr 14 , 2025Power 2+ Years of Zero Downtime in River MaintenanceClient Profile: - A specialized SME in inland waterway maintenanceProject Scope:Annual maintenance of a 15km urban river channel, managing mixed sediment including sand, mud, and debrisThe ChallengeBe...

Apr 14 , 2025Power 2+ Years of Zero Downtime in River MaintenanceClient Profile: - A specialized SME in inland waterway maintenanceProject Scope:Annual maintenance of a 15km urban river channel, managing mixed sediment including sand, mud, and debrisThe ChallengeBe...

- Maximize Your Dredging Efficiency with Premium Rubber Suction Hoses

- Sewer Seal Ring: Securing Urban Infrastructure

- Applications of Polymer Materials and Composite Materials in Marine Rubber Seals

- Case Study: Small Dredging Project at a Local Marina

- Durable and Reliable Rubber Dredging Hose Solutions

- Flexibility and Customization: The Core Competitiveness of Dredge Rubber Hoses

- Maintenance Tips for Prolonging the Life of Your Dredging Hoses

English

English